Digital Domain Solutions.

By conceptualising, developing, and delivering services in the digital space, vectral can minimise the complexity and cost of your project.

vectral specialises in developing and testing solutions in a digital space to eliminate costly surprises during construction and deployment.

-

vectral provide 2D and 3D mechanical design services ranging from industrial installations to small-scale personal projects.

-

vectral can assist you with understanding, developing, and deploying lightweight modern database solutions to your inventory, time, business intelligence, and client data requirements.

-

First-principles analysis of logistics, statistics, and mechanical systems. Fully qualified mechanical engineering is used to support all design work.

-

Modern systems allow solutions to be comprehensively tested in a digital space before making the decision to deploy. By comprehensively exploring your solution in a virtual space, vectral can save you time and cost by the time you need to deploy.

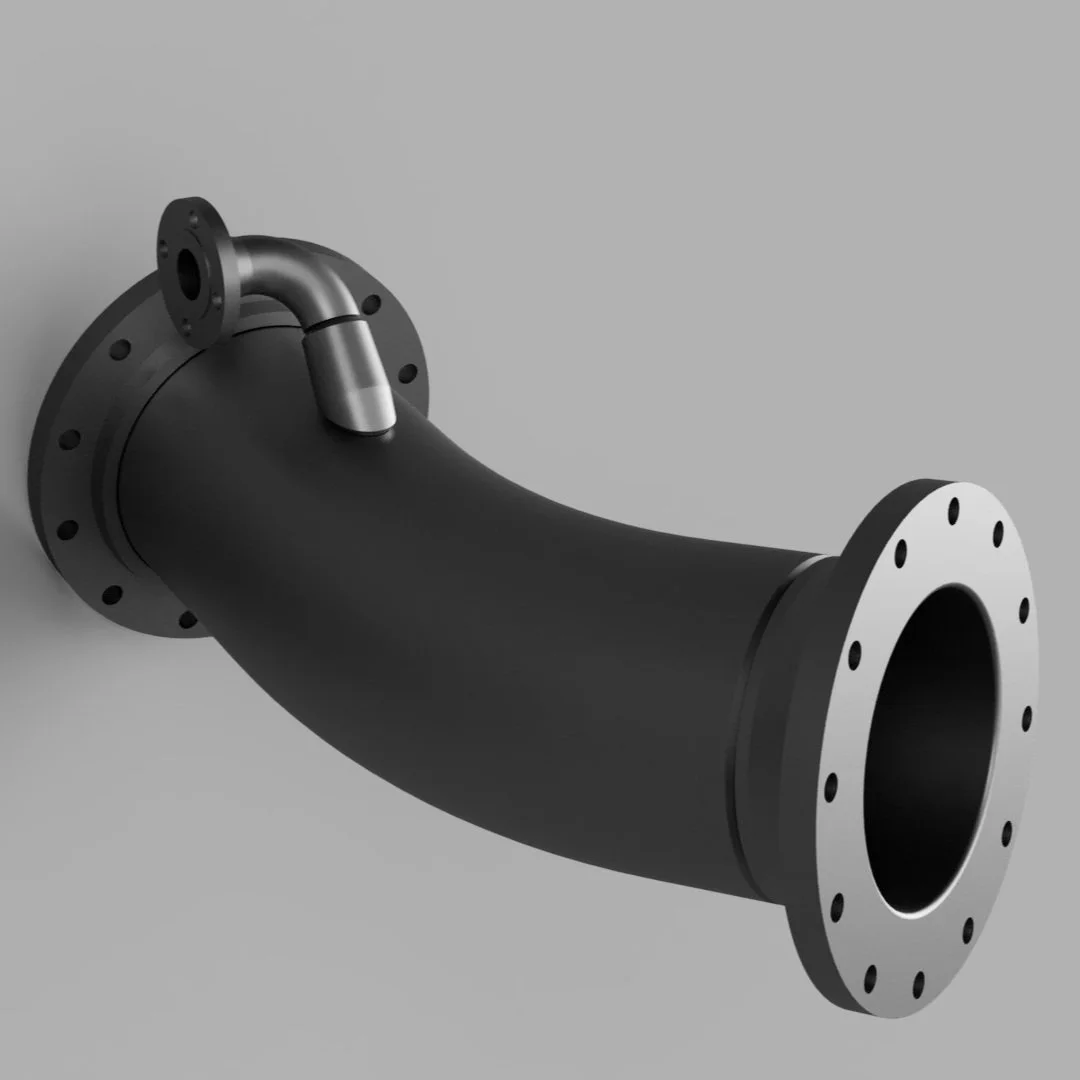

Mechanical Design

vectral have extensive experience in design for retrofit, modification, or fitment in existing facilities. Examples include:

Brownfields piping installations.

Cabinetry and furniture design.

Ductwork.

Mechanical equipment components (brackets and custom mounts).

Chutework and conveyor transfers.

Utilising the latest laser scanning technology, rapid prototyping, and full-context 3D models allows vectral to provide a constructable, operable, and ergonomic design.

DEM Modeling

Especially useful in debottlenecking projects, DEM models have been an effective tool for transforming observations and material properties into a window to the internal flow mechanics for a range of bulk materials handling scenarios. This is particularly useful in the early design phase for concept development, or in conjunction with a detailed design team to refine a design.

Reach out to discuss the limitations and potential for DEM modeling in your bulk materials handling design.

CFD-DEM Coupling

Case Study: Spouted Bed Coffee Roaster

It was possible to replicate, to a reasonable degree, the behaviour of coffee beans in a small fluid-bed roaster consisting of a blower, heater coil, and cylindrical hopper. Starting with measurable and observable data is key in developing a simulation that can then be used for developing a design.

If you have any requirements for advanced multiphase modelling, please get in touch. There are a range of methods for approaching various scales and types of solids-in-fluids problems, including modelling reaction kinetics and chemistry.

Multiphase PIC Models

Simulation of a loop seal on a lab-scale reactor discharge.

Settling slurry (600 µm, 25 %w/w) in a DN200 pipe loop.